Centuries of

Rotation

1738

LAWS OF FLOW

Daniel Bernoulli publishes his groundbreaking work on fluid dynamics, establishing the mathematical principles that would later govern pneumatic conveying and airlock design. His work on fluid pressure and velocity formed the basis of pneumatic conveying.

1760s-1790s

PRESSURE CHAMBER RESEARCH

James Watt's research on sealed pressure chambers influenced industrial valve and enclosure design, contributing to the development of pressure differential control systems.

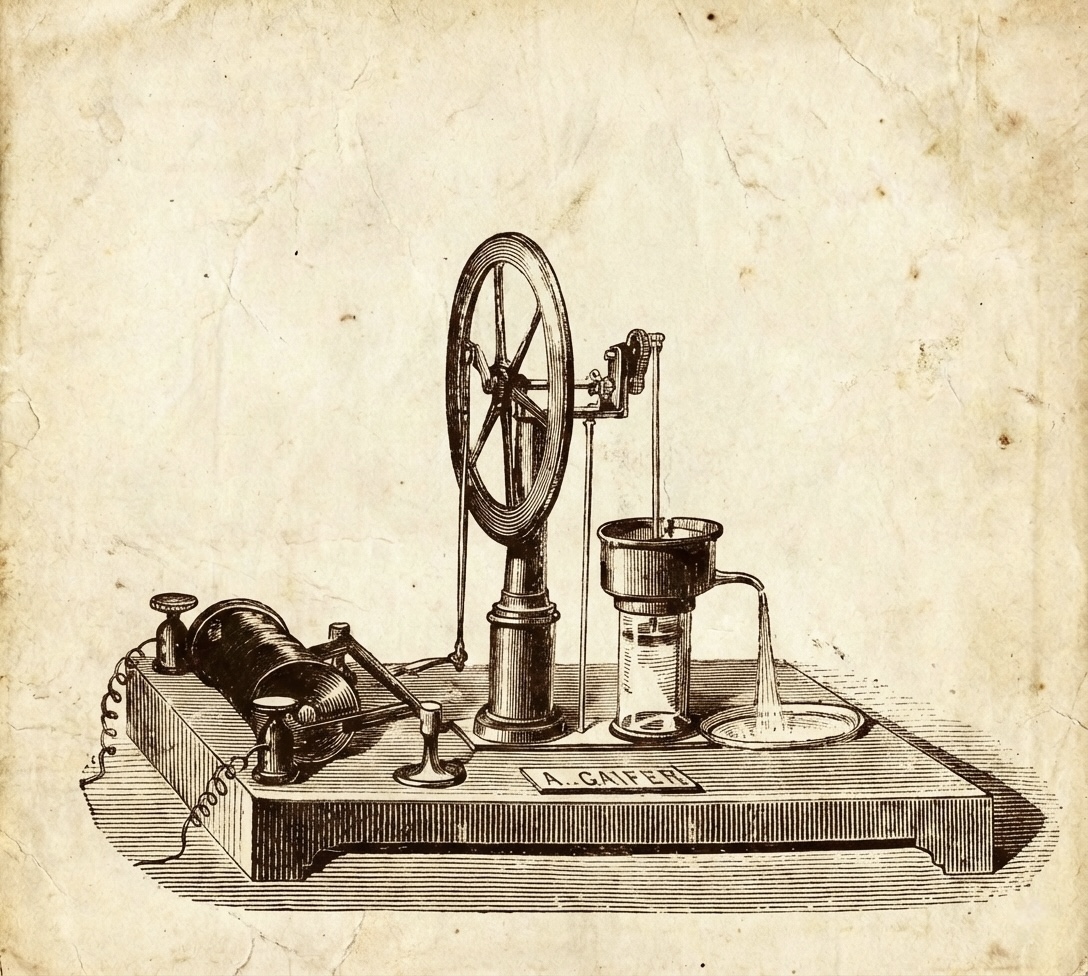

1800s

IRON & GRAVITY

Early gravity-fed and manually driven rotary feeders were developed for grain mills and flour processing. Constructed from cast iron and wood, these devices introduced the idea of continuous, non-clogging material flow.

Early 1900s

BIRTH OF THE AIRLOCK

The rise of pneumatic conveying in cement, coal, and chemical industries demanded dust control and pressure isolation. Engineers such as Albert Atwood and Henry G. Dietz pioneered dust-tight rotary valves, transforming feeders into true airlocks.

1950s

INDUSTRIAL STANDARDIZATION

Post-war industrial expansion required reliability and safety. Precision machining enabled tight rotor clearances, and hardened steels improved wear life. Rotary air locks became standard components in bag filters, cyclones, ESPs, and silos.

1980s

ADVANCED SEALING

PLC-based control systems, wear-resistant linings, and improved sealing materials emerged. Dr. Karl Meissner (Germany) advanced low-leakage and near-zero leakage rotary sealing concepts, particularly for fine powders.

1985

PEW (OSWAL GROUP)

The Oswal Group entered industrial equipment manufacturing, developing rotary systems for real-world plant conditions.

1. Scientific Foundations of Rotary Air Lock Engineering

The rotary air lock is governed by two core engineering principles:

- •Pressure Differential Control – enabling the transfer of solids between zones of different pressure while preventing air leakage.

- •Positive Displacement Feeding – delivering a fixed, repeatable volume of material with each rotor revolution.

These principles trace back to Daniel Bernoulli (1738), whose work on fluid pressure and velocity formed the basis of pneumatic conveying, and James Watt (1760s–1790s), whose research on sealed pressure chambers influenced industrial valve and enclosure design.

2. Evolution Across Industrial Eras

1800s – Industrial Revolution

Early gravity-fed and manually driven rotary feeders were developed for grain mills and flour processing. Constructed from cast iron and wood, these devices introduced the idea of continuous, non-clogging material flow.

Early 1900s – Birth of the Airlock

The rise of pneumatic conveying in cement, coal, and chemical industries demanded dust control and pressure isolation. Osborne Reynolds' research on airflow behavior enabled engineers to design sealing systems. Engineers such as Albert Atwood and Henry G. Dietz pioneered dust-tight rotary valves, transforming feeders into true airlocks.

1950s – Industrial Standardization

Post-war industrial expansion required reliability and safety. Precision machining enabled tight rotor clearances, and hardened steels improved wear life. Rotary air locks became standard components in bag filters, cyclones, ESPs, and silos.

1980s – Precision & Automation

PLC-based control systems, wear-resistant linings, and improved sealing materials emerged. Dr. Karl Meissner (Germany) advanced low-leakage and near-zero leakage rotary sealing concepts, particularly for fine powders.

3. Oswal Group

1985 – PEW (Oswal Group)

The Oswal Group entered industrial equipment manufacturing, developing rotary systems for real-world plant conditions.

The rotary air lock was shaped by centuries of science.